The torque and angle sensor module set is designed to be quick to integrate into any gear/BB/mid-drive/hub-drive/industrial design.

The torque and angle sensor is based on Sensitivus’ market-leading strain gauge technology. It uses a rotating low-power strain gauge sensor with an inductive power and data coupling for a non-contact interface to a stationary part of the sensor. This stationary part includes an inductive angle sensor and a digital interface for fast and secure data output of both torque and absolute angle.

On top of torque and absolute angle, the module outputs the calculated rotational speed (also called cadence in RPM, rotations-per-minute) optimized for fast start/stop as needed for e-bike applications. Temperature is also measured by the rotating part to allow for the safe handling of extreme temperatures and the detection of rapid temperature changes.

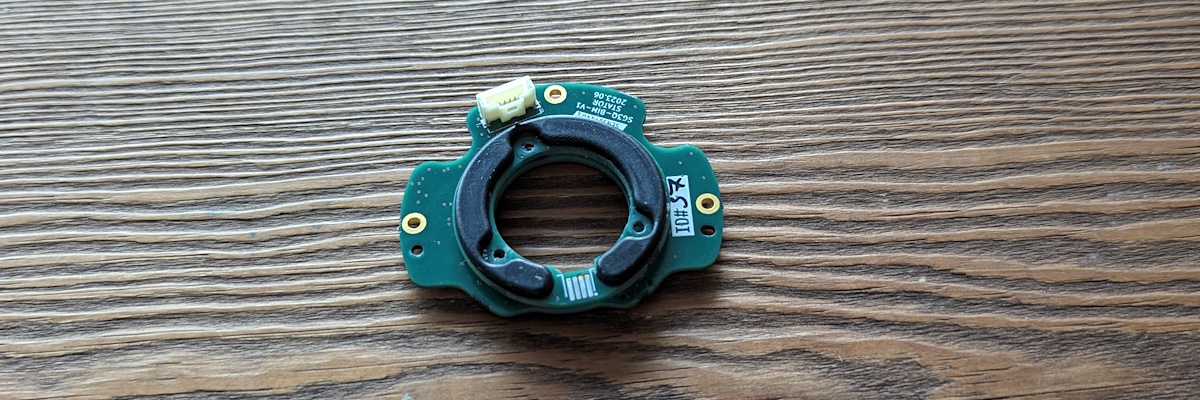

To protect the sensor system from humidity, water, grease, oil, etc. while also making the unit robust for manual handling, the SG30 sensor module set is delivered with an overmold of Technomelt™.

For an even faster evaluation of the technology, this module is the core of the SG210 reference design, which is ideally suited as a quick start technology evaluation.

Features

- Fast torque, angle, temperature, and cadence output

- Contactless, zero friction, and magnet-free

- No dead-band, fully linear positive and negative torque

- Low power consumption

- For e-bikes, EV/LEV, and industrial

- No residual torque effect, zero hysteresis

Specifications

Measurement

- Torque range typical -300Nm to +300Nm

- Torque resolution: 4096 steps/LSB ~ 12 bits

- Absolute angle: 0-359 deg in 1 deg steps

- Cadence: -220 RPM to +220 RPM (derived from angle)

- Sample rate: 1000 Sa/s (1 ms sample period)

Mechanical

- Designed for tube/shaft-shaped torque sensing metal

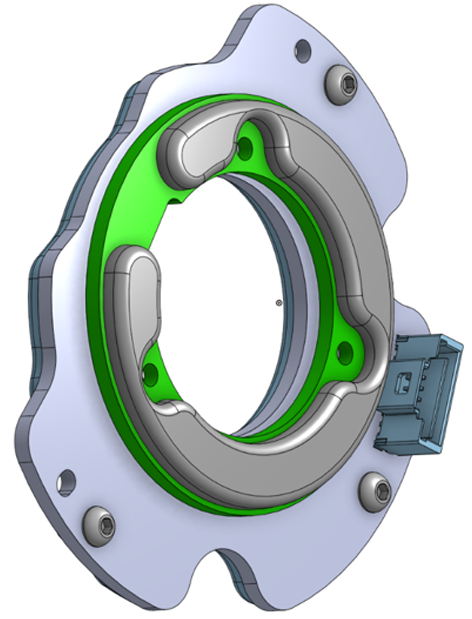

- Inner diameter: 23 mm

- Outer diameter rotor: 36.5 mm

- Outer bounding box dimensions stator: 55 x 45.75 mm

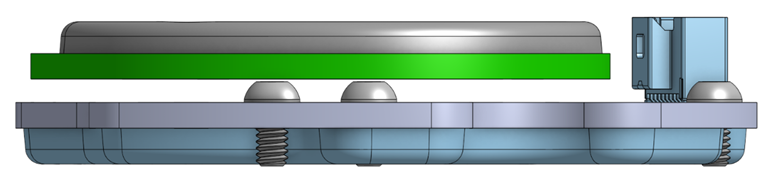

- Axial length (rotor + stator + 1.5 mm airgap)*: 9 mm

- Airgap range (axial direction): 0.3 to 2.5 mm

Strain gauges

- Designed for full-bridge (half-bridge optional)

- One or two shear-type strain gauges

- For off-the-shelf or custom strain gauges

Interface

- Serial interface: UART 0-3.3V levels, 230 400 baud, N81

- Simple binary protocol including CRC**

- Connector: 8-pin Molex 5013310807 (vertical SMT)

- DC 4.5V to 5.5V, 50mA max

General

- Temperature range (operational): -20C to +85C

- Protection/waterproofing: Overmolded for IP67 using Technomelt™

*) Not including connector, rotor holder, and strain gauge.

**) According to GD10950 (request copy) or customized

Documentation

For more about the SG3Q technology used and to download even more information:

To understand why torque sensors based on strain gauges are superior to torque sensors based on the magnetostrictive/magnetoelastic principle in e-bike applications, read our white paper comparing the two.

Illustrations

The module set as seen from the side. Notice the two screws for holding the stationary part (stator) are placed outside the airgap between the two parts.

Here the module set is seen from an angle to better show the relation between the two parts of the module set in the system. The green is the rotating (rotor) PCB with the dark grey illustrating the overmolding.

Applications

See examples of the contactless torque sensor module in various customer application designs in the references section. We see applications ranging from high-end E-MTB over urban e-bikes to 2-seater light electric vehicles and industrial applications.

For an overview of the different technologies used to make e-bike torque sensors, please see the technology comparison.

SENSITIVUS GAUGE

SENSITIVUS GAUGE