Sensitivus provides 100% customized torque/cadence sensors for a perfect fit for new e-bike designs. Read our customer application e-bike case studies to get detailed information on our innovative solutions.

E-bike Case Studies

CASE STUDY 1: Binova needed to optimize the drive unit for high power, torque, and perfect control for maximum riding fun. The unique side-mount motor design needed a customized solution.

CASE STUDY 3: VO Vehicles was searching for an e-mobility torque sensor for its unique two-rider solar taxi. The solution was a small diameter sensor as it had to fit into a diameter of 32 mm.

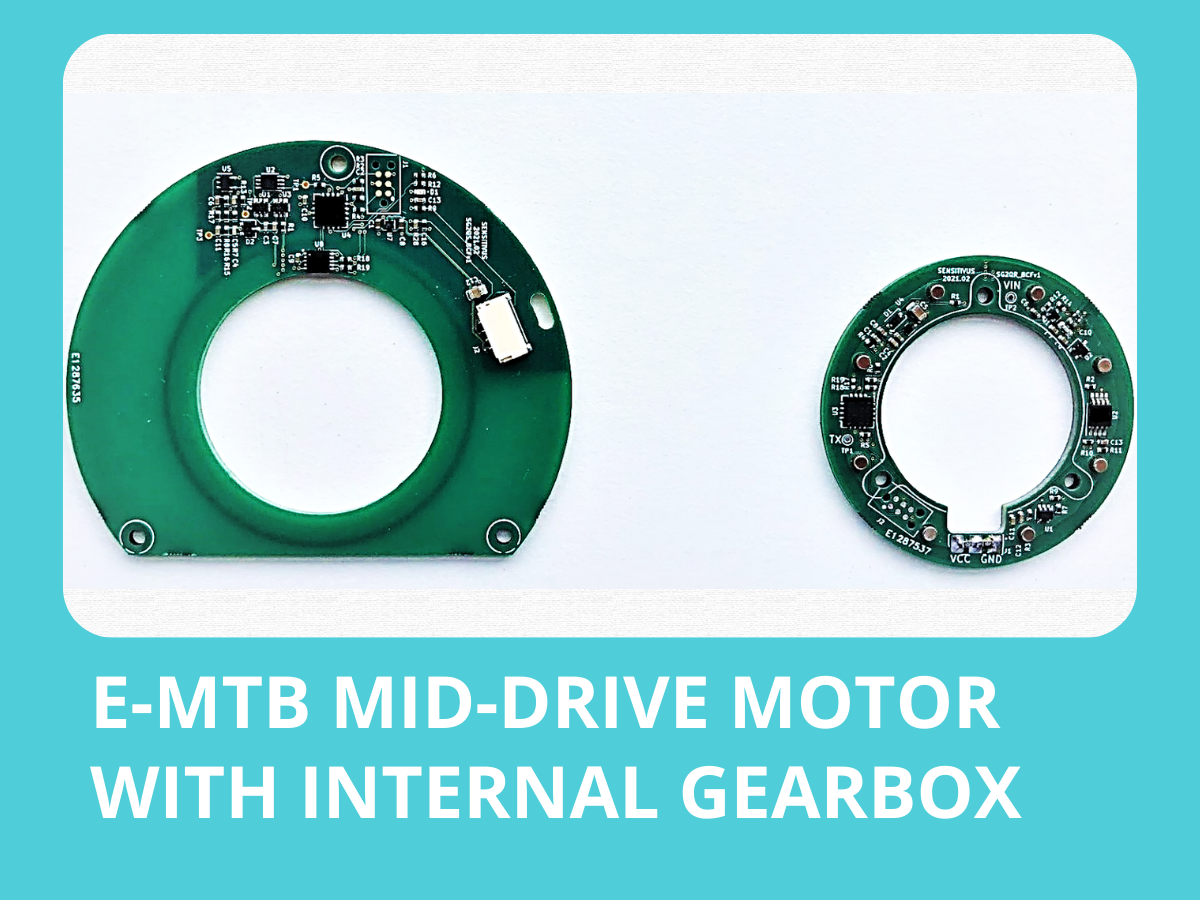

CASE STUDY 2: For this innovative high-end eMTB cycling brand, the mechanical constraint was a more complex 3D bounding box. The sensor had to be integrated into a perfect fit.

CASE STUDY 4: Fitting into a width of only 5.1mm, this customization was made to fit into a very compact automatic electronic gearbox/motor mid-drive unit.

Our e-bike case studies are meant to inspire. Do you have a need for a custom-made solution for your product? Get a customized torque/cadence sensor for a perfect fit for your e-bike designs.

SENSITIVUS GAUGE

SENSITIVUS GAUGE