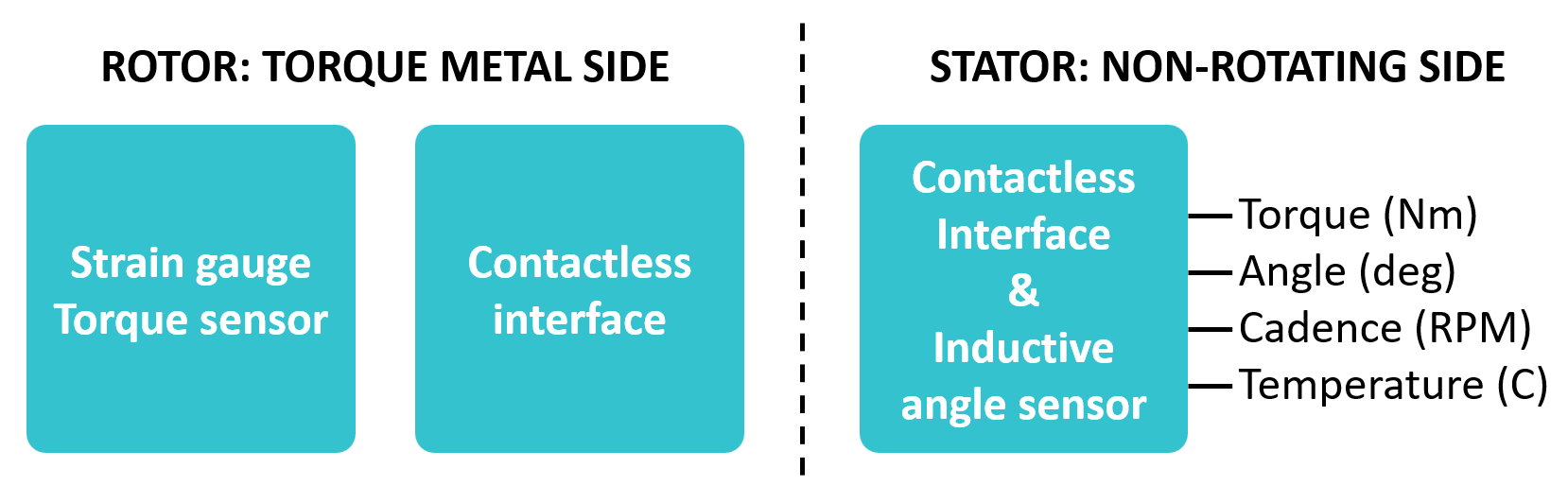

Zero friction, low power consumption, low latency, and magnet-free are the key features of the technology. The torque sensing is based on strain gauges and is easy to use with any type of metal. Fits all shapes of tube/disc/spoke sensing metal configurations.

The sensor interface is customized to fit any motor controller. The absolute angle sensor is based on an inductive sensing technique. Cadence is derived from the absolute angle with 1 deg resolution.

Designing e-bikes for less than 100 ms pedal-input-to-motor-output delay is key to safety (predictability), ride feeling (fun), and improved battery range. The SG2Q/SG3Q technology was created to help you do just that. SG3Q is the latest generation of this sensor technology.

Features

- Fast torque, angle, and cadence output

- Optional temperature and inclination

- Contactless, zero friction, and magnet-free

- No dead-band, fully linear positive and negative torque

- Low power consumption

- Fully customized to fit the application

- For e-bikes, EV/LEV, and industrial

- No residual torque effect, zero hysteresis

Specifications

Torque

- Range: -200Nm to +200 Nm, fully customizable

- Resolution: 4000 steps, typ. 4-10 steps/Nm

- Accuracy: ±1-2 % typical

- Linearity: ±1-2 % limited by customer’s metal

- Latency: 5 ms ±1 ms [analog], 1-2 ms [digital]

- Frequency response: Typical 500 Hz

- Analog output: Optional, fully customizable

Electrical

- Sample rate: 1000 Sa/s (1 ms)

- Interface: Custom. Analog/Serial/I2C/SPI/CAN/Modbus/IO-link etc.

- Power supply: Custom. Typical 3.3-5.5Vdc or 4-13.5Vdc

- Power consumption: Max 50mA

Angle

- Range: 0-359 deg absolute

- Resolution: 1 deg

Cadence (angle based)

- Range: ±220 RPM

- Latency to stop: Custom. Max 40 ms (5-220 RPM)

- Angle to start: Custom. Max 1.5 deg

Environmental

- Operating temperature: -20°C to +85°C (typ within 1 Nm)

- Protection: Overmolding, potting, sealing, or coating to IP67+

Documentation

Description

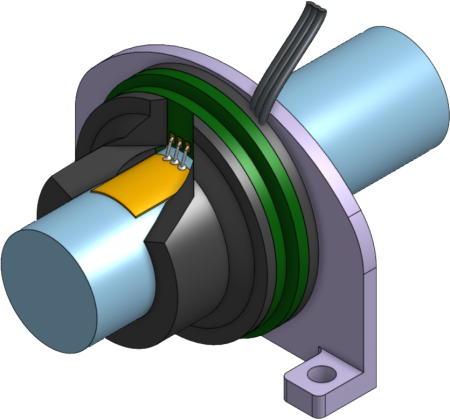

The SG3Q module set is designed as a very responsive contactless torque sensor module. It is suitable for a range of applications involving torque measurements on any rotating system using a strain gauge sensor. A prime example application is an e-bike mid-drive motor for higher-end e-bikes where responsiveness and accuracy are key to providing the best rider experience.

By using wireless power and data transfer, the rotating torque shaft side is free of any batteries. A one-millimeter air gap between the rotor part and the stator part provides a friction-free solution. The sensor is ideal for reliable measurement of static and dynamic torque on both non-rotating and rotating components. Integration into an e-bike system is easy as the sensor is customized to any form factor needed.

Zero friction and low power consumption for the high accuracy achieved is the key feature of the technology, along with its compact design and customizable form factor.

See the sensor technology roadmap to see how designing for the future starts with SG3Q today.

High reliability through the use of automotive qualifiable components (AEC-Q).

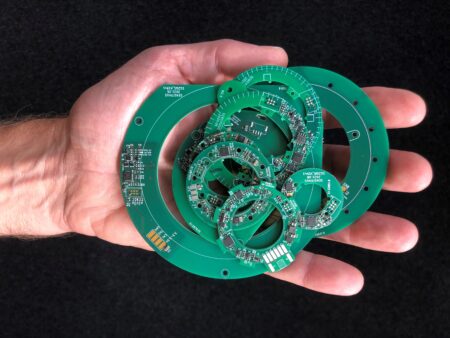

Form factor

For a radially constrained design, a typical OD is from ID + 15mm. For an axially constrained design, a typical OD is from ID + 30mm. In the axial direction, the typical minimum size is 4mm plus mechanical fixation (also depending on strain gauge type).

See also the Customer form factor examples catalog for some of the many sensors created with this technology

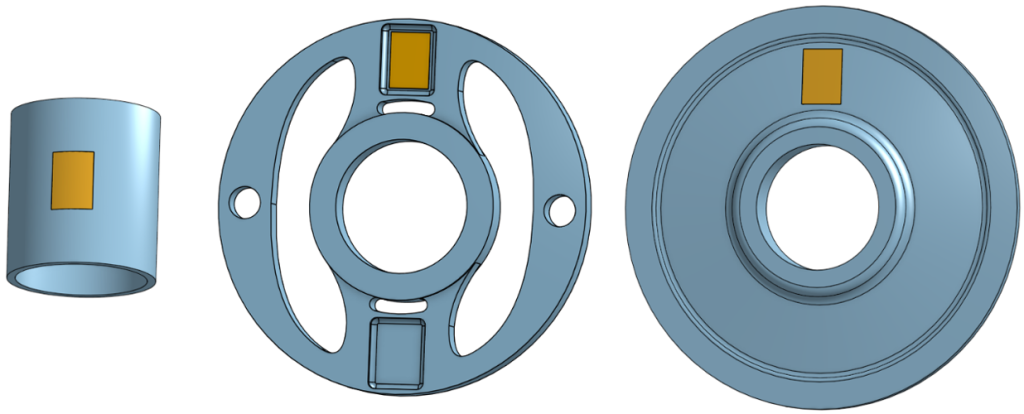

Torque-sensing metal

The torque-sensing metal shape can be any shape that works well for the particular application. The below illustration shows some typical shapes from a conceptual point of view: tube, spoke design, and disc shape. The type of metal is not important, although most designs are optimized to maximize surface strain to improve noise performance.

All metal shapes have advantages and disadvantages. To customize a sensor design for optimum performance in a specific application, please inquire about our online torque-metal-design workshop where we help you design a good solution and show how you can predict the performance of the sensor with FEA.

Applications

See examples of the contactless torque sensor module in various customer application designs in the references section. We see applications ranging from high-end E-MTB over urban e-bikes to 2-seater light electric vehicles and industrial applications.

For an overview of the different technologies used to make e-bike torque sensors, please see the technology comparison.

FAQ

SENSITIVUS GAUGE

SENSITIVUS GAUGE