CASE STUDY: E-MTB MID-DRIVE MOTOR WITH INTERNAL GEARBOX

The French company coming out of the automotive industry is creating a new high-end eMTB cycling brand. It was clear to them that they need a responsive torque sensor to give their e-MTB design the optimum performance and perfect ride feeling.

What they were still missing was a sensor that would fit into their very compact internal gearbox. Standard solutions would not fit and would compromise the mechanical design of the unique motor/gearbox combination.

SOLUTION: A CUSTOM E-MTB TORQUE SENSOR

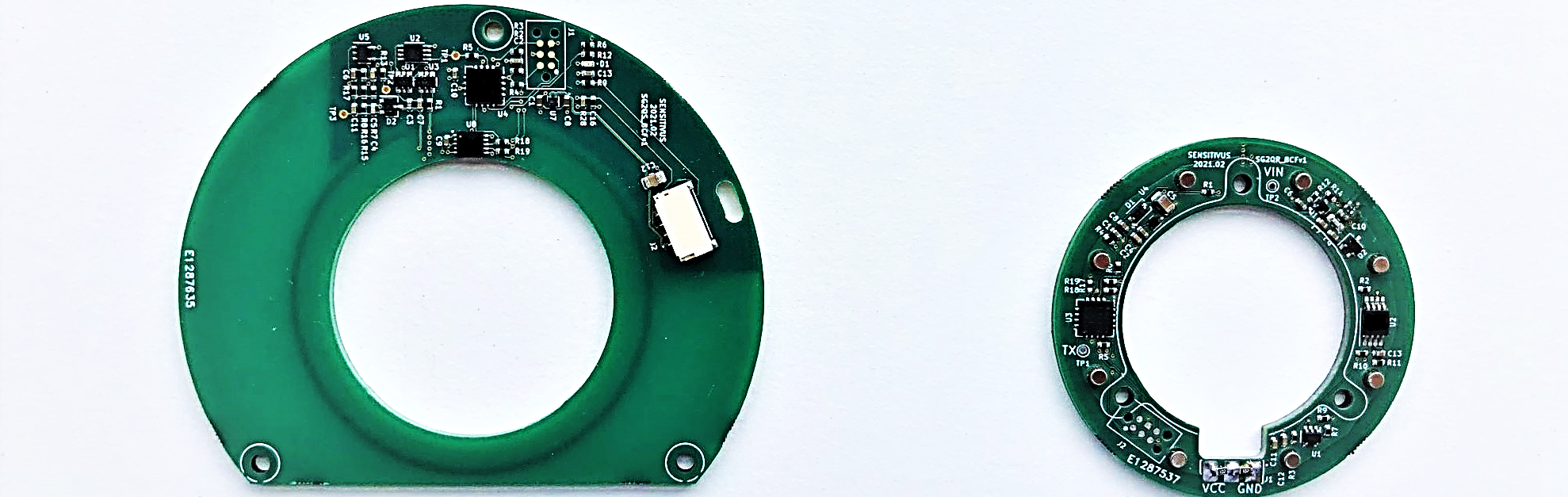

Sensitivus created a minimal electronic sensor solution to fit exactly across the smallest tooth wheel of the gearbox. The special gearbox design required a partially cut for a perfect fit on the stationary PCB. The electronic components were moved according to the desired shape of the board.

The design included an interface protocol that was easy to implement on both the sensor and the integrated bike controller. Both cadence and torque are communicated on a simple serial link with 100 updates per second. This allows for a really responsive system, where the perceived delay from pedal action to motor action is virtually undetectable.

With a low power consumption of 50 mA at 5 V, the air gap between the stationary PCB and the rotating PCB could be increased to 1.6 mm. Even with some margin for mechanical tolerances.

CONCLUSION: SUCCESSFUL INTEGRATION

The French company managed to integrate the contactless e-MTB torque sensor design right into the gearbox. As a result, this new line of e-MTB designs will be as responsive as possible. Exactly as customers in the high-end e-MTB market would expect. At the same time, this is making the bikes more fun and safer to ride.

If you want to understand why we have selected a contactless torque sensor based on strain gauges as the best solution to this sensing challenge, please see the full e-bike torque sensor technology comparison.

STATUS: PROTOTYPE

Get in touch below so we can start discussing how to customize this technology to fit your application.

Or maybe learn that one of the existing customizations is close enough to what your application requires.

SENSITIVUS GAUGE

SENSITIVUS GAUGE