CASE STUDY: E-MOBILITY TORQUE SENSOR

For many types of electric assist vehicles falling under the broader term of e-mobility, getting the perfect “ride feeling” requires a fast torque sensor. This helps optimize the drive system, the electronics, and the interaction of all the components. An e-mobility torque sensor is an integral part of the optimization process and will continue to play an important role in the future development of e-mobility vehicles.

This British company was searching for an e-mobility torque sensor for its two-rider vehicle. They needed two sensors for each vehicle but interfaced in a way where the electric assist would feel smooth even with the bigger natural variations between the two riders’ efforts. This challenge is mostly for the motor/vehicle controller.

Another challenge for this design was the space constraints in the radial direction. The whole sensor needs to fit everything into a diameter of 32 mm with a 15 mm axle.

SOLUTION: A CUSTOM E-MOBILITY TORQUE SENSOR

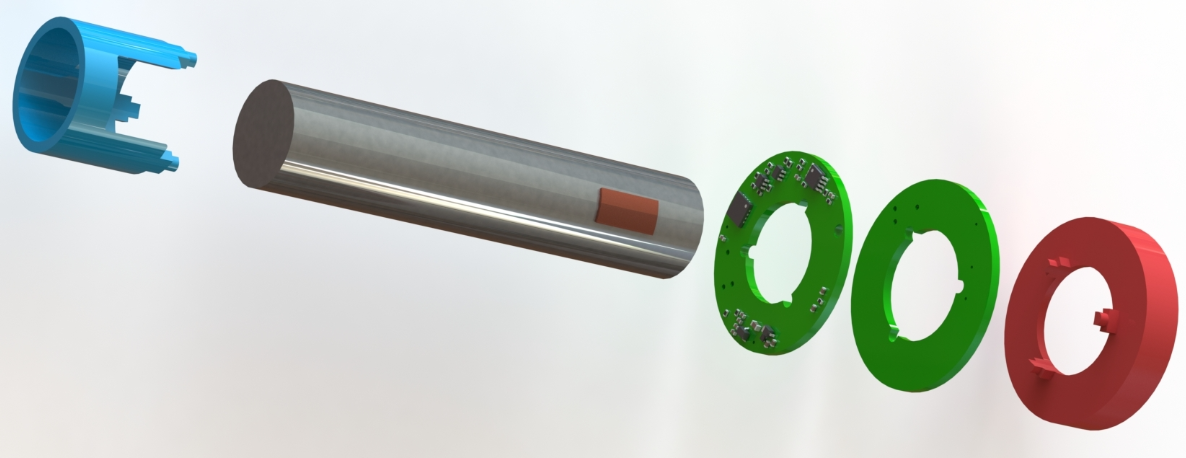

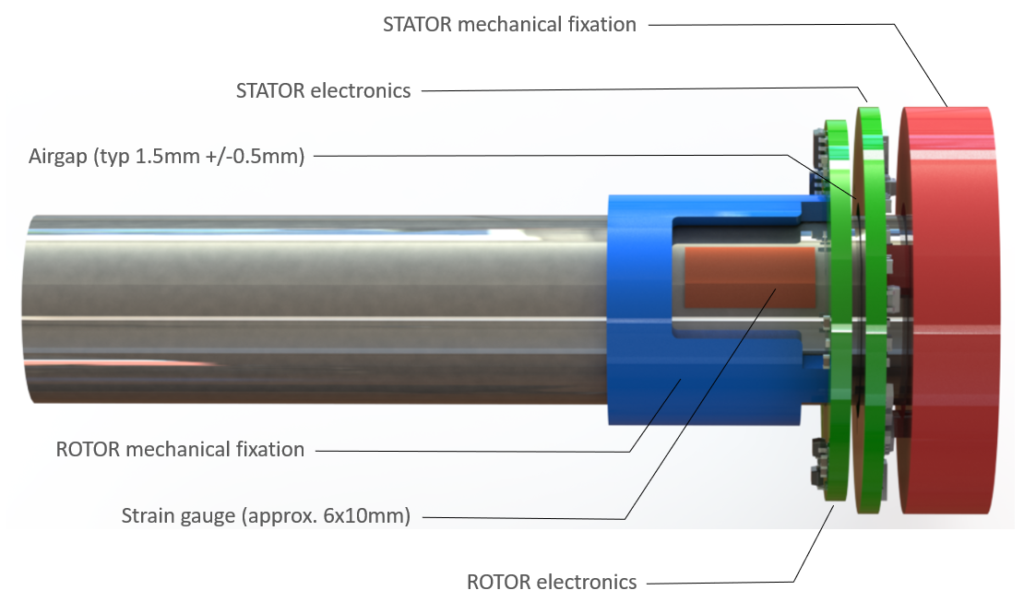

With such a radially constrained design, the solution was to utilize more of the axial direction. Two plastic parts were designed to hold the ROTOR and STATOR electronics parallel with a 1 mm air gap. By carefully designing the mechanical fixation only a minimal area of the printed circuit boards is blocked. By reducing the number of steps per rotation in the cadence sensor, it was possible to fit everything in. All this without having to use techniques that would be more expensive to prototype or manufacture.

CONCLUSION

Inner diameter (ID) and outer diameter (OD) can be customized on both ROTOR and STATOR. Typical ID values are from 15mm to 100mm. For a radially constrained design, a typical OD is from ID + 15 mm. In this case, it worked for a 15 mm axle with all of the electronics inside a 32 mm diameter.

The British company was guided throughout the whole process and provided with the best solution for the mounting and design of the mechanical parts. Like this, the company managed to integrate the e-mobility torque sensor into its very unique two-person vehicle design. As a result, this new line of vehicles will be very responsive while, at the same time, providing maximum safety to the users.

If you want to learn why we have selected a contactless torque sensor based on strain gauges as the best solution to this category of sensing challenges, please read the full e-bike torque sensor technology comparison.

STATUS: PROTOTYPE

Get in touch below so we can start discussing how to customize this technology to fit your application.

Or maybe learn that one of the existing customizations is close enough to what your application requires.

SENSITIVUS GAUGE

SENSITIVUS GAUGE